Recording causes of the problems and defects of the process

Prerequisites

- Access to the File > Process (PM022) menu.

- Previously created process.

- Access to the File > Cause (PM056) menu.

Introduction

It is possible to enter the process analysis record through the analysis tools available in SoftExpert Suite. Available tools are 5 whys, FTA, and Ishikawa.

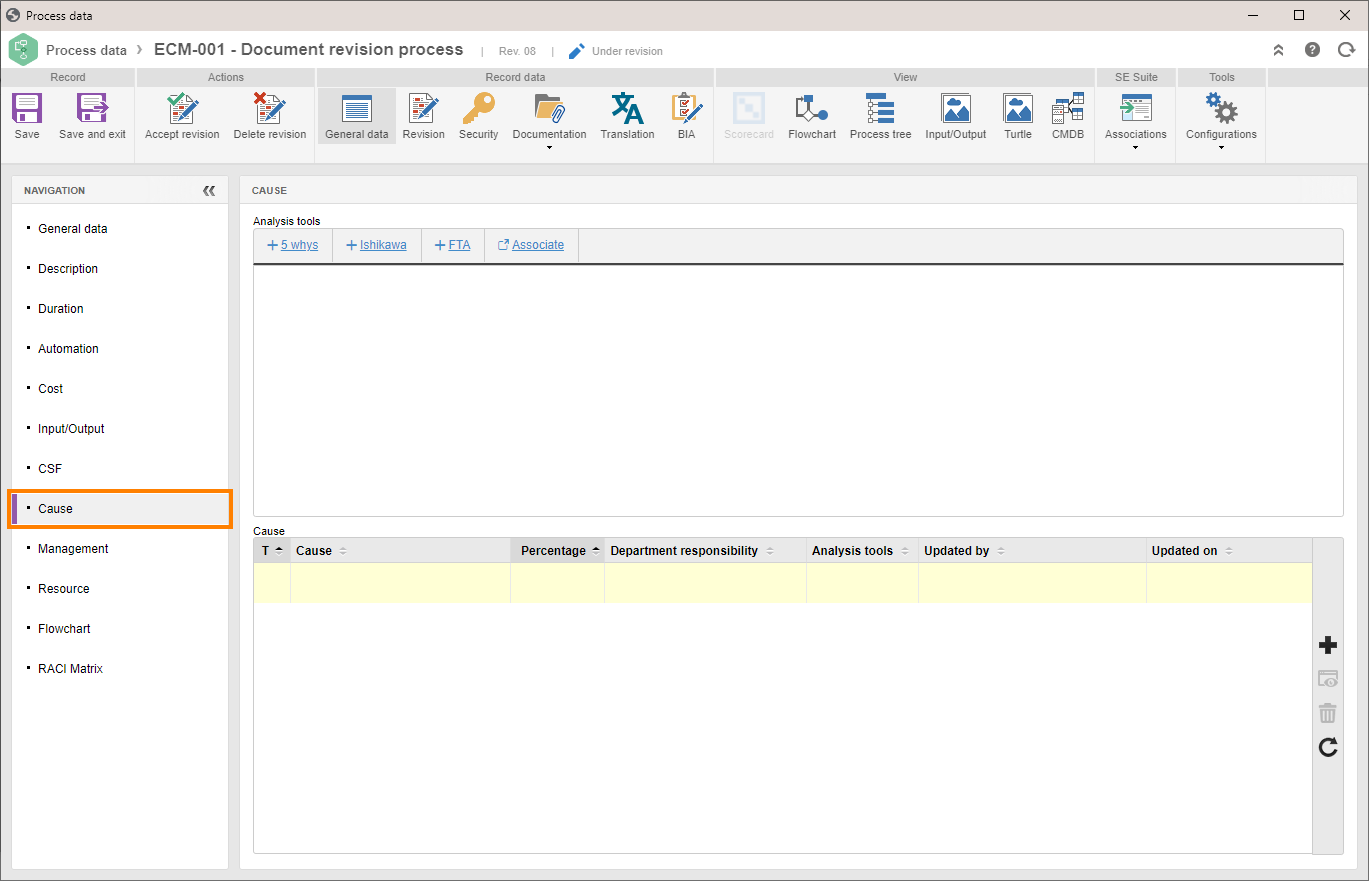

On the Cause tab of the process data screen, there is a section named Analysis tools, in which the user can create a new analysis or associate existing analyses.

The system also allows associating causes of process defects or problems.

This article will teach you to record causes in the process data. For our example, we will associate the “Incomplete purchase order” cause.

Recording causes of the problems and defects of the process

1. Access the File > Process menu (PM022).

2. Search for and select the process whose cause you wish to record.

3. Click on the arrow next to the  button and select the Process data option.

button and select the Process data option.

4. On the left side of the screen, click on the Cause tab.

5. Click on the  button.

button.

6. Select the cause. Click on the  button to search for a previously created cause or on the

button to search for a previously created cause or on the  button to record a new cause.

button to record a new cause.

7. Enter whether the selected cause is a root cause or a potential cause.

8. Enter the percentage of the selected cause in relation to generating the defect or problem in the process.

9. In the department responsibility field, click on the  button to search for and select the department in which the cause was generated.

button to search for and select the department in which the cause was generated.

10. If necessary, enter a description for the cause of the problem or defect in this process.

11. Click on the  button.

button.

Add as many causes as necessary.

Conclusion

The causes of the process problems and defects will be recorded, facilitating monitoring.

If no other configurations are necessary, click on the Accept revision button to release the process.