Create an internal calibration with measurement data collection

To create an internal calibration, simply follow the steps below:

1st step: Creating a standard activity with measurement data collection

The objective of the standard activity is to define the steps and information necessary to execute a calibration activity.

To create a standard activity, access the AS004, click on the  button, and select the "Costs" type.

button, and select the "Costs" type.

On the screen that will open, fill in the following fields:

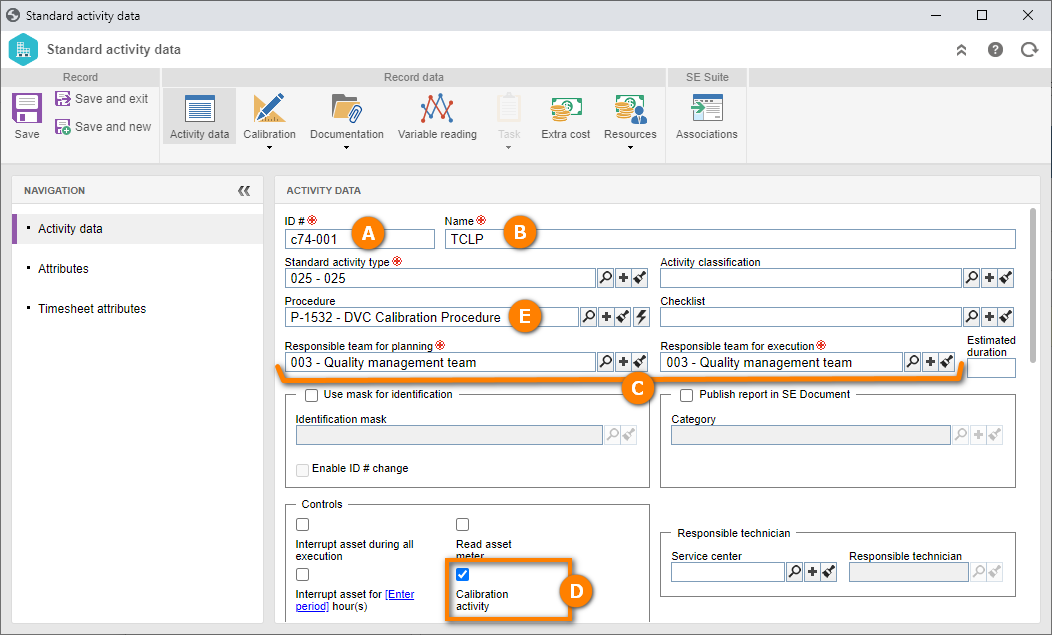

- ID #: C74-001.

- Name: TCLP.

- Planning and execution team: Select a team previously created in the system, of which your user is part.

Then, check the Calibration activity option and, in the Procedure field, search for "DVD Calibration procedure".

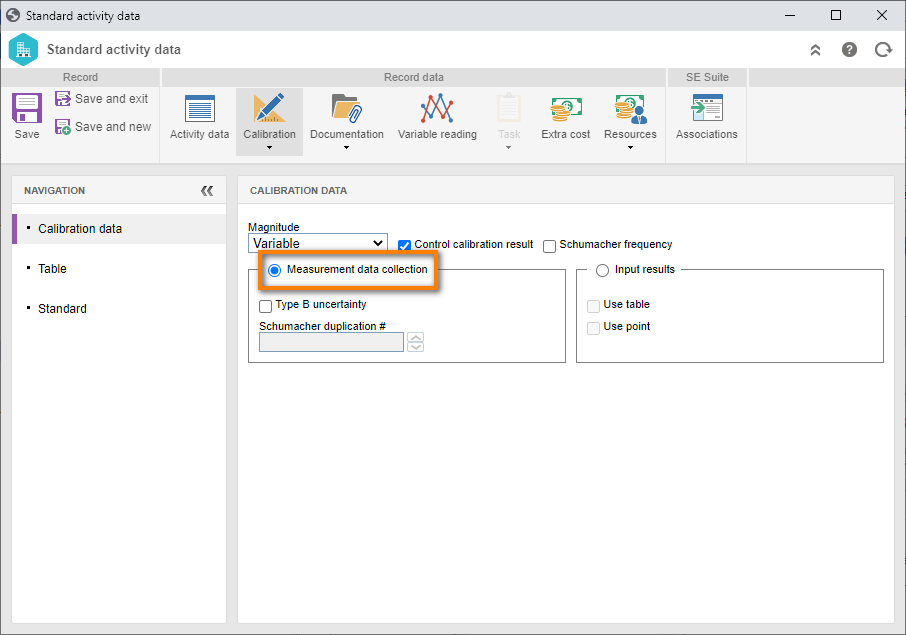

After that, access the Calibration > Calibration data tab.

On the screen that will be opened, select the Measurement data collection option.

Feito isto, acesse a aba Tabela, clique na seta ao lado do botão  e selecione a opção "Novo".

e selecione a opção "Novo".

Na tela de dados de configuração da tabela, preencha os seguintes dados:

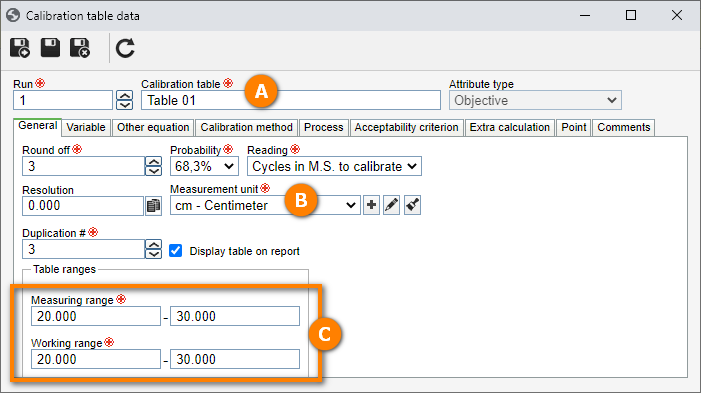

- Calibration table: Table 01.

- Measurement unit: Centímeter.

- Measuring and working range: Enter the values "10" and "20"..

After doing that, click on the  button.

button.

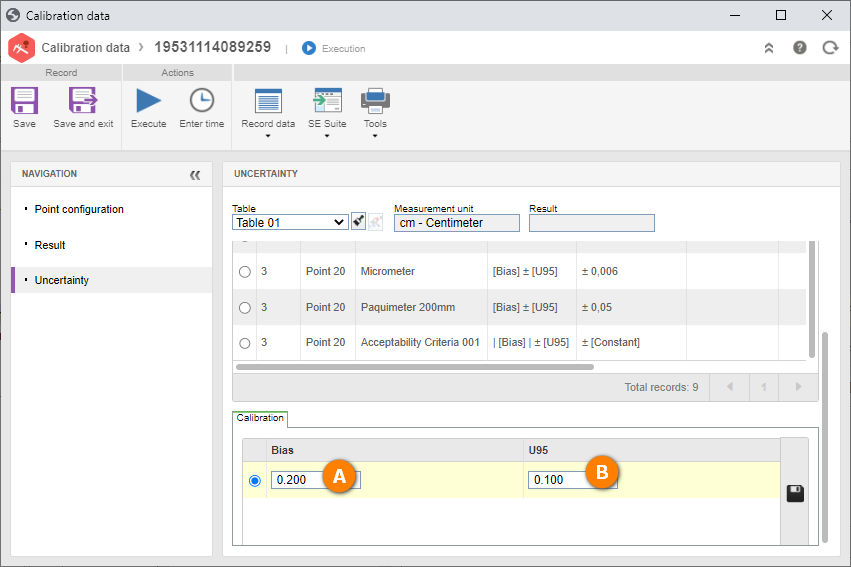

Now, on the Acceptability criterion tab, we will configure the equation and the constant once again.

To do so, click on the arrow next to the  button and select the "New" option.

button and select the "New" option.

On the screen that will open, fill in the ID # field with "REF", and the Name field with "Reference".

Then, click on the  button next to the Equation field.

button next to the Equation field.

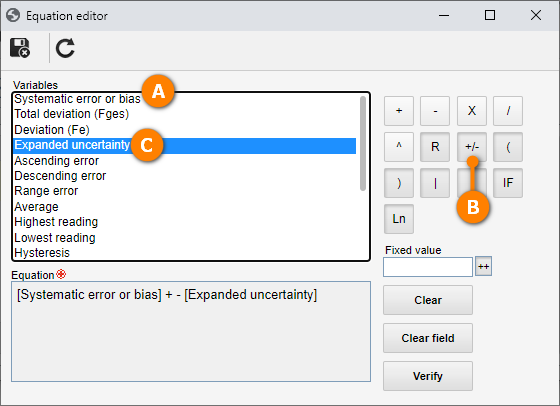

For this example, select the "Trend" and "Expanded uncertainty" options, according to the image below.

After doing that, click on the  button.

button.

After defining the criterion, we will define the acceptable value for the system, that is, the value range that will be accepted as approved for your equipment.

To do so, click on the  button next to the Acceptable value field and, on the screen that will be displayed, select the "Constant" option.

button next to the Acceptable value field and, on the screen that will be displayed, select the "Constant" option.

After that, click on the  button.

button.

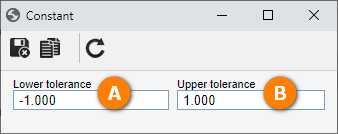

At this point, the configuration is ready to be used; however, we will define the value of the constant that the system will interpret as valid.

To do this, click on the  button and, on the screen that will be displayed, enter the value "-1000" for the lower tolerance and "1000" for the upper tolerance.

button and, on the screen that will be displayed, enter the value "-1000" for the lower tolerance and "1000" for the upper tolerance.

That is, when the system calculates the criterion, the calibration with the formula result between -1 and 1 will be approved.

Once done, click on  .

.

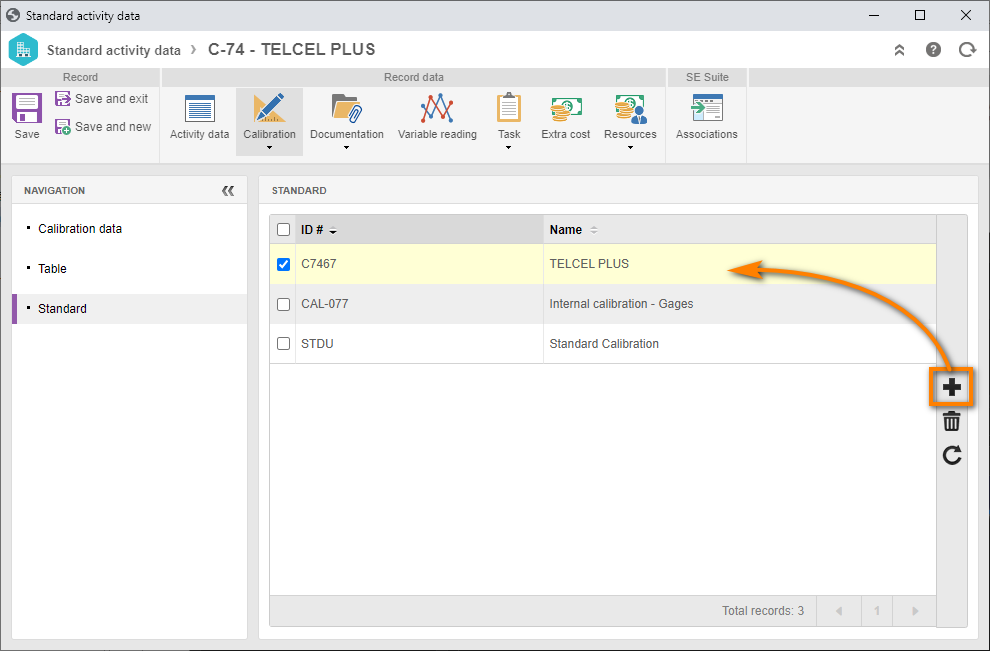

Now, access the Standard tab, click on the button and, in the Quick search field, select the "TELCEL PLUS" activity.

After doing that, click on the  button.

button.

2nd step: Creating an activity with a standard

To create a calibration with measurement data collection, access the CL008 menu; in the Quick search field, search for the "Metric square" plan and click on the  button.

button.

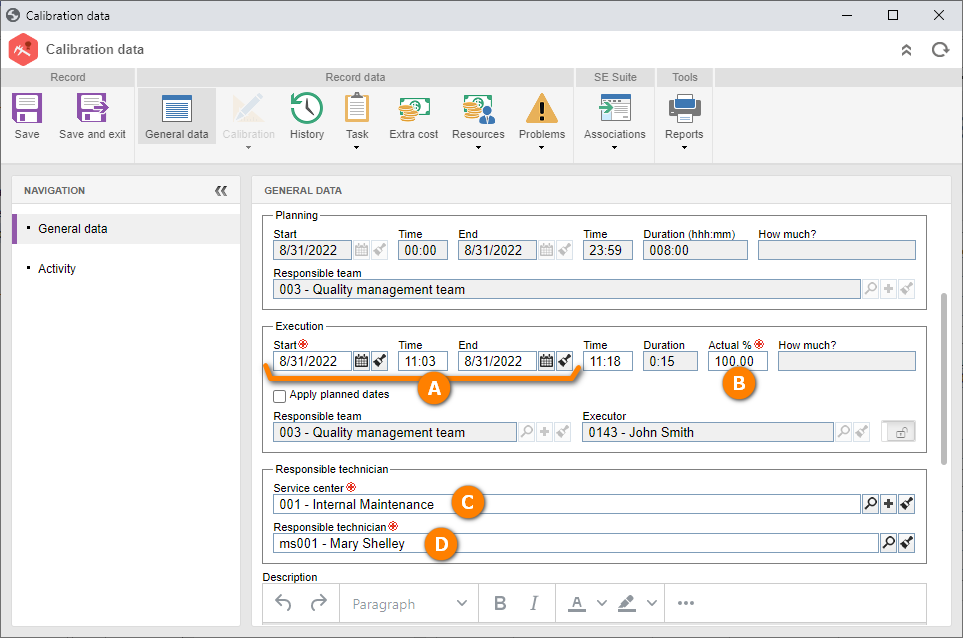

On the execution screen, fill out the Start date and time, Actual, Service center, and Responsible technician fields in the activity, according to the image below.

After doing that, click on the Save button.

By saving the activity, the system will leave it under execution and the option with the calibration data enabled.

Now, access the Standard tab and click on the  button.

button.

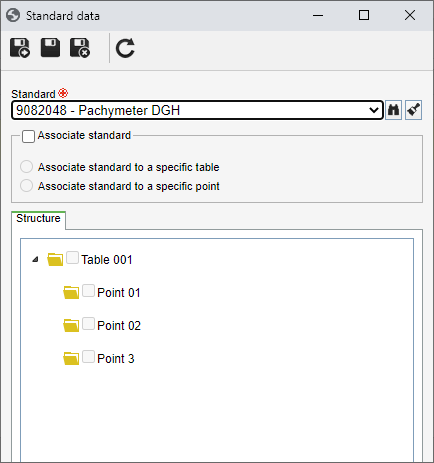

On the screen that will be opened, enter a standard activity, according to the image below.

All assets calibrated in the system that used the standard activity associated in this screen can be used as the standard, as long as they have a valid calibration activity.

After doing that, click on the  button.

button.

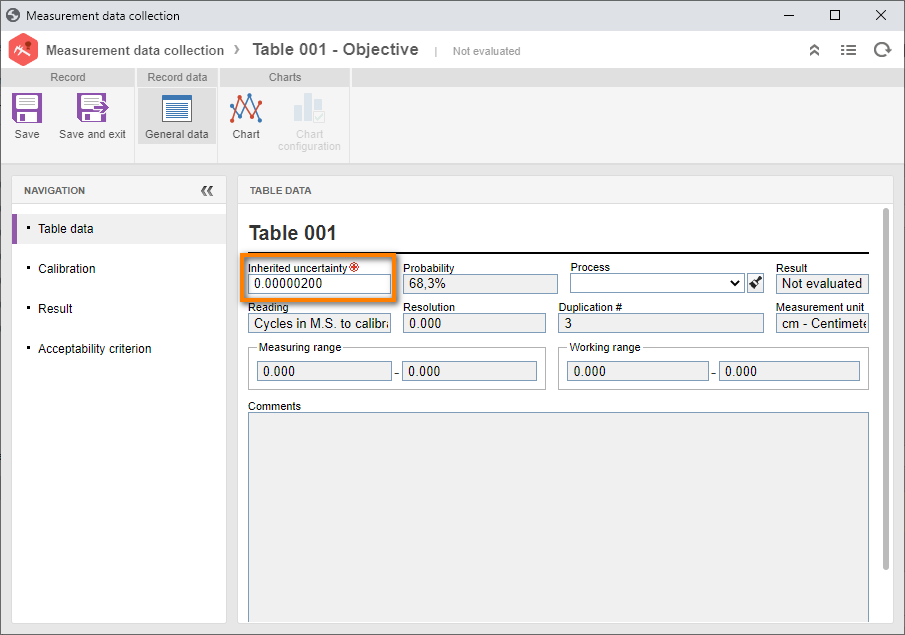

Then, in the Measurement tab, click on the  button and fill out the Inherited uncertainty field.

button and fill out the Inherited uncertainty field.

This field corresponds to the known error of the gage, such as those predicted by the manufacturer.

By executing this process, the calibration activity is finished.

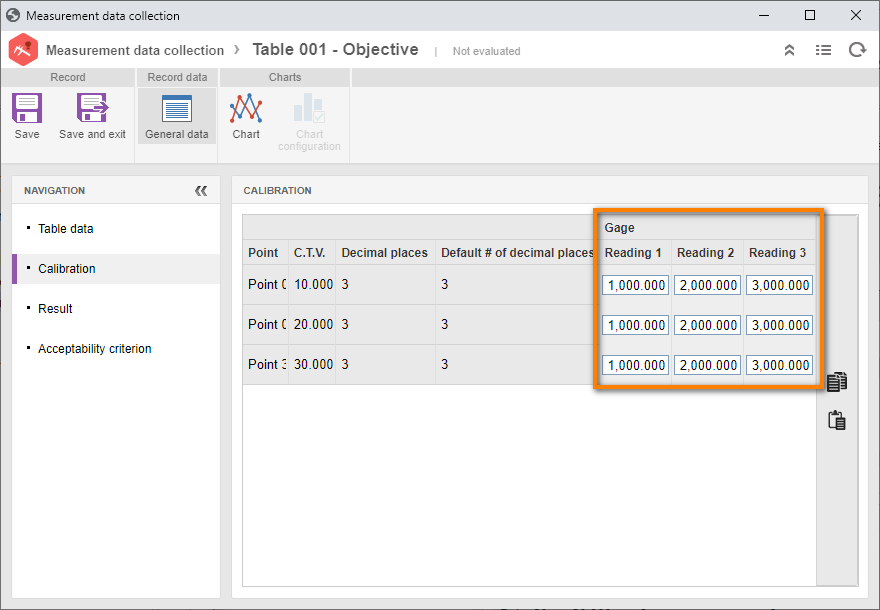

Then, the readings performed in the gage are added to the Calibration tab. These configurations come from the standard activity.

After the addition, the system will calculate the criterion and the system variables.

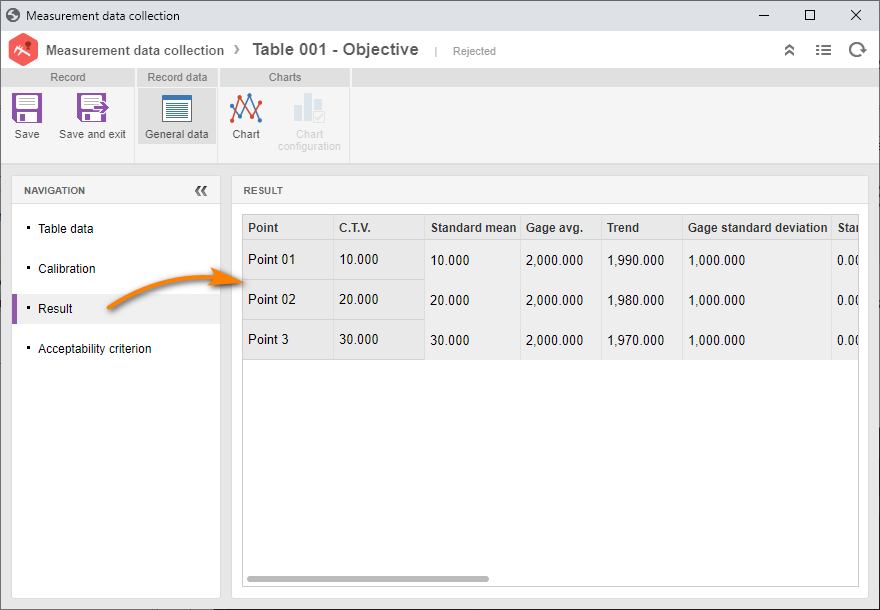

To view the system calculations, select the Result tab.

After doing that, click on the Save and exit button.

Now that the measurements have been performed, we will name the technicians who took part in the equipment calibration process.

To do so, click on the Enter time button.

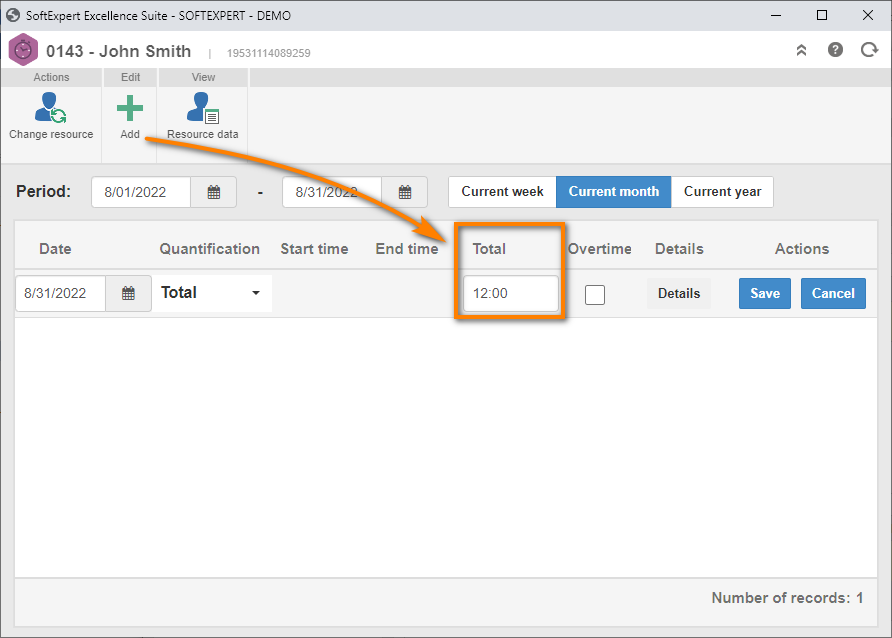

On the screen that will be opened, click on the Add button and enter the total number of hours spent in the activity, according to the image below.

Then, click on the Save button and close the timesheet screen.

Now, click on the Execute button and, on the result confirmation screen, click on the  .

.

Thus, the internal calibration with measurement data collection has been successfully created!